Invest in an integral part of your production with a Kalmar Reach Stacker. Kalmar Reach Stackers increase your productivity, reduce fuel consumption and lower your emissions with the innovative technology of the Kalmar Eco Reachstacker.

Increasing fuel costs and tougher carbon emissions standards means you need a reach stacker that is leaner and greener while still maintaining the highest levels of operational productivity when lifting containers or handling other materials. The Kalmar Eco Reachstacker provides you with an eco-efficient solution that is guaranteed to use significantly less fuel than other reach stackers. Cutting your fuel costs and reducing your carbon emissions while enhancing your environmental reputation.

Compared to older reach stackers, our eco-efficient solution can reduce your fuel consumption by up to 40% and by up to 25% compared to more recent machines, cutting your fuel costs and emissions while matching the productivity levels of machines with much larger engines. This is backed up by the Kalmar Eco Reachstacker Fuel Saving Guarantee.

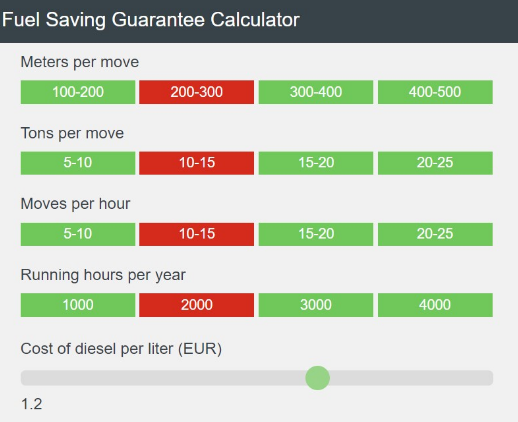

Knowing exactly what your fuel costs are going to be each month gives you a greater level of financial predictability, which is why Kalmar is offering a Fuel Saving Guarantee with each of its Eco Reachstackers. With an agreed and fixed level of fuel consumption, based on a set of agreed metrics on your cargo handling drive cycle, you will have complete control over your fuel costs.

Our Fuel Saving Guarantee includes:

Improving the working environment and safety of your drivers is extremely important, as it will enhance their productivity and reduce accidents. With our enhanced reach stacker driving experience, your operators will:

You can further enhance your reach stackers’ safety levels with our Safety Solution package, which includes a number of automated safety features that will make your operations even safer.

The Kalmar Eco Reachstacker 420-450E Range has been specifically designed to lift and stack containers up to six high and four deep and is also suitable for intermodal and barge handling applications. While the Kalmar Eco Reachstacker DRG500-700E is designed for industrial applications lifting much heavier loads and can be fitted with a variety of attachments including hooks and tool carriers.

We know that maintaining high levels of availability is important to you, which is why we have focused on speeding up regular service tasks. You can now take quicker oil samples, get easier and safer access to electrics and your transmission is faster to service as it can be calibrated at higher temperatures. Saving you time and money.

Kalmar also offers an extensive range of Genuine Spare Parts for reach stackers including tyres which can be ordered easily once you have registered for Kalmar MyParts, our digital parts ordering and management system. There is also a full range of service and support packages available with Kalmar Care that are designed to keep your reach stacker moving.

Kalmar Stage 3, 4 & 5 Eco Reachstackers fitted with Volvo engines are certified to use HVO100 Fuel which complies with EN 15940 standard. By switching to HVO100 Fuel you will cut your CO2 emissions by up to 90% from day one.

Kalmar Insight can provide you with real-time operational information on your Kalmar Eco Reachstacker to review and analyse, allowing you to take action that will help improve your overall operations immediately. Kalmar Insight can also help you manage maintenance tasks across your fleet more effectively with the Kalmar Insight Maintenance Module.

You can have your Kalmar Eco Reachstacker fitted with the Kalmar Load Measurement System, which records the precise weight of every load your reach stacker handles or lifts and records this information automatically in Kalmar Insight. This system is SOLAS compliant and can also be fitted to most other reach stackers.

Our new range of Kalmar TL2 Terminal Tractors have been designed by combining our local knowledge and insights with the accumulated knowledge of manufacturing over 60,000 terminal tractors globally. In 1958 Kalmar built the first Terminal Tractor and since has stayed at the front of the market by focusing on delivering high-quality machines with innovative features that have a positive impact on the productivity of your business. Our latest machine is built on our tested and proven platform, so you get a reliable and robust machine that can handle the harshest conditions. Our TL2 Terminal Tractor is built to last.

With over 10,000 machines built globally on our tested and proven platform, you can expect a terminal tractor that is ready to take on your toughest tasks. Using our proven platform, you get a common electrical system and standardised control panels, making it easier for your driver to change machines.

You get a highly stable and robust bolted chassis design, which is easier and quicker to maintain, repair, or change than a welded chassis. This will reduce the time repairs take and are more flexible should you want to change the chassis in any way in the future.

Smart programming combined with our highly efficient driveline can reduce your overall fuel consumption by up to 15%, saving you money and reducing your carbon emissions substantially at the same time.

Our new Essential cabin has been designed to keep your drivers comfortable and in control, even when working in difficult situations. The cabin is fitted with an improved climate control system and has an adjustable seat and steering wheel to ensure your driver is happy and operating at their best.

All our machines are built on a common platform with the same error codes for fast and easy troubleshooting.

All our new machines have similar operator controls and interfaces, making it easier to move from one type of machine to another.

With the TL2 Essential’s hydraulics system you have fewer moving parts to service and maintain over mechanical alternatives, saving you even more time.

With an easy lift cabin and all service points accessible from the ground, servicing will be safer and quicker.

With industry leading service intervals, your terminal tractor will spend less time being serviced and more time operating in your yard.

The Kalmar TL2 Essential Terminal Tractor features non-slip access surfaces and handrails for easy and safe access to the cabin and rear platform.

Our new cabin has improved visibility both forwards and to the rear platform, so your driver can operate safely at all times.

In addition to a range of engines, axles, and 5th wheels, there are many other options that you can specify to meet your business requirements. Here are just a few you might want to consider:

Kalmar Heavy Terminal Tractors fitted with a Cummins engine are certified to use HVO100 fuel which can reduce your carbon emission by up to 90%. If you own an older certified machine, you just need to discuss with your local Kalmar support team if your equipment needs a minor upgrade or if it is ready to start using HVO100 straight away.

Our range of Kalmar Essential Terminal Tractors is ready to be connected to Kalmar Insight, a real time equipment management tool. With Kalmar Insight, you can track the performance, fuel consumption, view shocks and alerts and manage your equipment maintenance activities, allowing you to continually optimise the performance of your trucks.

The Kalmar Essential Terminal Tractor delivers on Kalmar’s reputation of delivering realisable and well built equipment – making it great value for the price. The Essential Shunt or Yard truck is built with quality materials and parts, which makes not highly reliable truck that will take less time and effort to maintain in comparison to older trucks.

The Kalmar Essential Shunt or Yard Truck has a bolted chassis, not a welded chassis. This makes servicing and maintaining the chassis easier and reduces the risks of cracking which is a common issue with a welded chassis.

Kalmar’s container handling reach stackers offer you best of

everything. With low operating and maintenance costs, powerful

performance, and superior comfort, safety and usability, you’ll find a

solution to suit your project.

The new-generation Gloria DRG420–450 combines the reliability of previous models with new innovation that better meets the safety and operational needs of the driver. The ergonomic cabin features enhanced visibility and intuitive displays and electrical controls. Experience comfortable performance and increased efficiency, even in the most demanding of operations.

For proven simplicity and durability, the DRF400–450 is the working horse of reach stacker models. Smooth, driver-friendly and powerful, this truck has been extensively tested to endure and excel in high-strength day-to-day operations. Suited for all kinds of intermodal handling, this is the perfect machine to supplement an existing fleet.

One of the most flexible container handling solutions, the DRT reach stacker combines high-powered performance with high-cost efficiency. It loads containers quickly and efficiently in all sized spaces thanks to its enhanced visibility and maneuverability features.